3D-Printed Concrete Buildings Begin to Absorb Carbon

The Diamanti 3D-printed concrete project by researchers at the University of Pennsylvania is paving the way for structures that passively absorb carbon, thanks to its nature-inspired design and special material mix.

Engineers and architects at the University of Pennsylvania (Penn) are working to make concrete, one of the world’s most carbon-emitting building materials, part of the climate solution. Concrete is responsible for approximately 8% of global carbon emissions, and demand for it is rising every year with increasing urbanization. If even a fraction of this material could be redesigned to store carbon, its environmental impact could be significantly reduced.

Diamanti: A Structural and Environmental Innovation

The team, led by Professor Masoud Akbarzadeh, developed a 3D-printed structural system they named Diamanti. The system utilizes both geometry and materials science to transform concrete into a potential carbon sink.

Diamanti aims to reduce the carbon emissions resulting from concrete production. Instead of concrete poured into standard molds, the Penn team uses robotic 3D printing to produce modular components optimized with digital algorithms. Each piece is designed to withstand both compression and tension while using minimum material. The curved and hollow structures increase the durability of the building and expand the surface area, enhancing the interaction of carbon dioxide with the concrete, thus turning each module into a small carbon sink.

Stronger and Greener Materials

The primary component of cement, the main ingredient used in concrete production, releases high amounts of $\text{CO}_2$ when heated to temperatures up to $2,000^\circ\text{C}$. The Diamanti project reduces these emissions by replacing a portion of the cement with diatomaceous earth, a silica-rich material composed of fossilized algae. This additive was discovered to increase the porosity of the concrete, allowing carbon dioxide to diffuse deeper and chemically react with calcium-based compounds. Tests show that this modified concrete mix can absorb over 140% more $\text{CO}_2$ than traditional concrete under the same conditions.

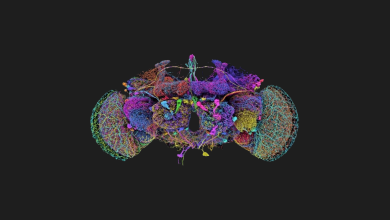

In addition to material innovation, the project is revolutionizing structural design. The researchers, particularly inspired by the porous framework of bone structure, used triply periodic minimal surface structures that efficiently distribute loads while keeping mass low. Thanks to robotic 3D printing, these complex designs can be produced without molds. This results in light yet strong components, using approximately 60% less material compared to traditional concrete.

Successful Demonstrations, Now for Full-Scale

To move beyond the lab, the team constructed a prototype bridge. The 2.5-meter bridge, exhibited at the European Cultural Centre’s “Time, Space, Existence” exhibition in Venice, consists of nine modular components printed with a robotic arm. Each piece has voids and surface textures that enhance both its durability and carbon capture capacity. The modules are joined with steel cables without the use of glue or mortar. This method reduces the need for steel reinforcement and allows the bridge to be disassembled and reused.

Following successful initial tests, larger prototypes measuring five and ten meters were tested at the CERIB research institute in France. The ten-meter-long model was printed with Sika’s concrete mix by the French robotics firm Carsey3D. After the successful demonstrations, researchers began planning the first full-scale bridge in France, with multiple potential sites being evaluated in Paris.

You Might Also Like;

- We Selected 10 Series Similar to Stranger Things for Those Who Love It

- Where and How is Silver Used in Electric Vehicles?

- Hyundai Unveils Its Multi-Purpose Wheeled Robot

Follow us on TWITTER (X) and be instantly informed about the latest developments…